7:00AM to 5:00PM

Has a severe drain blockage in the sewer pipes disrupted your plumbing system? Or have some tree roots damaged a particular pipe? You might’ve already got suggestions from neighbours and friends to reline the pipes immediately and call a reliable drain plumber from a pipe relining company.

Pipe relining is one of the most effective ways to repair damaged pipes—but what makes it such a great option for your sewer drains or pipes? And how does it actually work?

Here’s the short answer: Pipe relining allows us to fix broken or blocked pipes without the hassle of major digging. Thanks to advanced technology like CCTV drain inspections, we can carry out precise, non-invasive repairs that restore your pipes with minimal disruption. No more messy excavations—modern pipe relining takes repairs to the next level.

Want to know more? Our in-depth guide covers everything you need to know about trenchless pipe relining. Let’s dive in!

To help you understand the different aspects of pipe relining, we’ll begin by defining this technique for your broken drain repair. Subsequently, you’ll know about the details of the procedure, including the essential points to consider before deciding when calling for a pipe relining service. It won’t make you a pipe relining specialist, but it’s close enough.

The pipe relining process repairs broken or cracked pipes without digging for a blocked drain or another reason. It essentially implies creating a rigid, new pipe inside the cracked or damaged pipes by sealing off the cracks to promote better flow.

The relined part seals comfortably against the remaining pipe system, preventing further breaks and stopping leaks. This method is widely used for internal pipe repairs as it’s a more budget-friendly option. Moreover, pipe relining solutions are pretty convenient and don’t require the involvement of many professionals compared to pipe replacement.

Most plumbing companies use epoxy resin to create the new pipe, as it’s durable and facilitates normal water flow throughout. Companies often use their custom-made resin solution to make the pipes, as they’re built using patented technology devised by industrial chemists, polymer engineers, and R&D experts.

Let’s take a closer look at the steps involved in the procedure:

It starts with assessing the plumbing system. The plumber sends a drain camera down the pipes to locate blockages or breaks. They also measure the pipes during this process since these steps help determine where the problem lies.

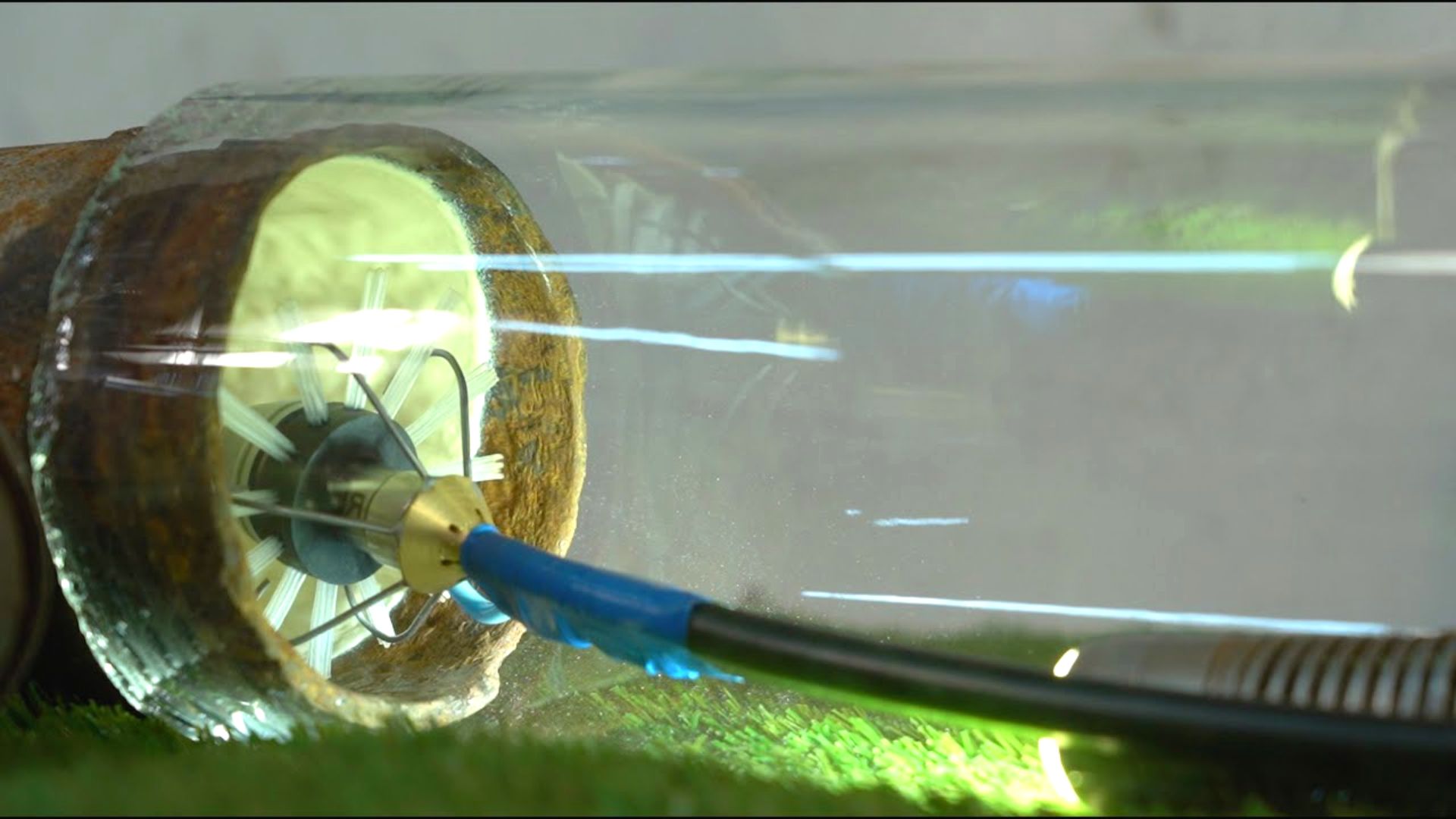

Next, the plumbers start cleaning the pipes, which can involve multiple steps. They use regular cleaning methods initially, while significant or solid blockages are removed with robotic cutters. Lastly, a high-pressure water jet is used to complete cleaning and ensure the surface pipes are blockage-free to set the resin pipe correctly.

After taking the measurements, the plumber will create a customised felt liner and a bladder to match the pipe specifications, including any junctions or bends.

Once the relined section is ready for installation, the felt liner is soaked in epoxy resin, and the uninflated bladder is inserted into the liner. After that, the plumber attaches a rope at both ends of the liner. The rope pulls the liner in place through the existing access points.

A specialised drain camera ensures that the liner is within the pipes. Then, the plumber inflates the bladder with air, and the felt liner blows out to create a seal against the pipes. Thus, a new pipe is formed that covers any cracks or broken areas.

The bladder stays inflated until the resin is cured, creating a rigid and hard pipe. The plumbers ultimately remove the bladder, leaving a brand-new, durable, watertight pipe.

After the entire procedure, there’s a last inspection phase, whereby the CCTV drain camera checks whether the installation and sealing are secure.

Pipe relining is the preferred mode of pipe repair in most cases, thanks to these advantages:

But there are some concerns associated with this procedure, too:

The relining procedure can be effective if enough precautions are taken beforehand. But in a few cases, it has some physical limitations, which you must remember.

Improper pipe cleaning can lead to uneven linings that may cause many problems later. Ensure you clean the pipes properly; hiring professional plumbers for maintenance multiple times a year isn’t enough.

Also, remember that the accumulated debris can create problems during relining.

Pipes less than 4 inches in diameter might create trouble, as epoxy needs some space to harden. But that isn’t always possible for smaller pipes.

You must replace broken pipe components, as simply relining the pipes won’t be enough to create a new outer pipe. So, make sure that the outer surface of the pipes is in proper condition before relining.

Relining has many more benefits than pipe replacement and is an efficient repair method. Depending on the material used, it can repair many pipe issues, ranging from tree root damage to cracks, lasting 20 to 50 years. You only need to dig a small hole to access the pipes, meaning the procedure hardly disrupts your landscaping or garden.

Also, it’s a beneficial method of preventing pipe damage, and houses with old pipes often have their pipes relined beforehand to avoid structural issues. After the pipes are relined, you can forget about tree roots or blockage damage.

Remember when we mentioned that pipe relining is a budget-friendly option for pipe repair? That’s because the process is more straightforward. It doesn’t involve any digging that can disrupt the house plan. But if we need to reline several pipes in and around the home, the cost involnaturally be much higher.

Pipe replacement is an intricate procedure involving various tools, materials, and labour. You will also need to consider the pipe depth and the area that must be excavated.

There you have it — a detailed yet simplified guide on the nitty-gritty of pipe relining.

Remember that checking your plumbing system occasionally is best, as you can reline the pipes on time. Ultimately, this will save you more time and money and help you stay stress-free.

Remembering the dos and don’ts of relining would be best to ensure you can benefit from the procedure. We’ll wrap things up for today, but stay tuned as we’ll be back soon with more informative content.

Please get in touch with our team if you would like to speak to a professional plumber about pipe relining. Gold Coast Plumbing Company technicians use the latest equipment and technology to repair your pipelines quickly and efficiently.

See you next time, bye!